TOP

For the earliest Epiphone models (< SN 5400) see : Reconstructing the 1931 Masterbilt model lineup. Epiphone acoustic archtop tops were carved from 2 inch thick blocks of fine grained spruce, that were split longitudinally and glued together side to side, often refered to as “bookmatched” (see Lutherie.net). After that, they were rough carved on machines, then handcarved and graduated to the final dimensions. Some war-time Epiphones had poplar tops (Jake Wildwood).

“Before cutting the f-holes, cloth (or wooden) strips were often glued in at strategic places to prevent splitting along the wood grain. There is also a cleat at the f-hole, obviously a later repair.” (Wiedler : close-up # 27)

BRACING

Epiphone archtop tops were parallel braced. For the earliest Epiphone models (< SN 5400) see : Reconstructing the 1931 Masterbilt model lineup. Bracing has two primary functions: it keeps the guitar from collapsing under string tension and it shapes the guitar’s sound. The term “parallel bracing” is actually a misnomer, because the bass brace does project in a different angle towards the endblock than the treble brace.

The bass braces had a rounded profile, while the treble braces were tapered to a fine edge. The ends of both braces were trimmed to enhance tone and to make neat joints with the kerfing of the top. The neck- and endblocks were generally made of mahogany.

LADDER BRACING “Some of the earliest Masterbilts before SN 5500 (which I date 1931) were ladder braced in stead of parallel braced.” (Wiedler, facebook 8/8/2021).

January 2022 luthier Dave Richard wrote on facebook: “Epiphone changed their bracing slightly (I believe) when they revamped their guitars in ‘36. IME, up to ‘35, both tone bars were of medium height, consistent thickness, and rounded on top. In ‘36, they both became taller, and tapered in height. At some point, in subsequent years, the treble bar remained ‘taller’, while the bass bar became ‘shorter’: treble bar tapered in height, but not the bass bar. I do believe that Epiphone modified and tweaked the bracing( in cross section, not layout) over the years from ‘31 to the late ‘40’s.”

BACK

The backs of the high-end instruments were carved in a similar manner to the tops and from solid blocks of the same woods as the rims: mahogany, maple or American walnut. Lower line instruments were made with pressed (solid and laminated) backs. see pictures

RIMS

The earliest rims were made from solid sheets of the same wood as the backs and hand bent to the proper shape. In 1940 Epiphone generally switched from hand bent solid sheet rims to machine pressed laminated rims. According to Wiedler (facebook 2 May 2021) the kerfed linings were replaced by solid linings around 1948-49.

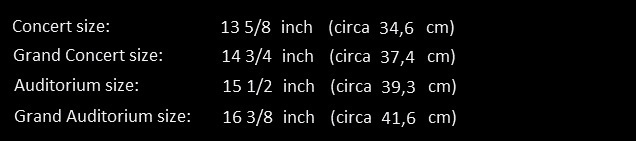

BODY SIZE

Body depth on acoustic Epiphone archtops was standard at 3 3/8 inch, though the actual depth could vary by as much as 1/8 inch, depending on the final thickness of the top and back. Epiphone used the following terms to describe body sizes:

In 1935 all Epiphone guitars were raised one body size : 17 3/8 inch (circa 44 cm) and 18 ½ inch (circa 47 cm) for Emperor and some De Luxes. This advanced size was introduced in response to Gibson’s move to larger sized instruments.

CUTAWAY

The single Venetian cutaway – first utilized on the very limited production of the Soloist in 1940 – was offered as a standard option on the Emperor, De Luxe, Broadway and Triumph. Wiedler wrote us July 2015: “In the 1948 March 15 price list the cutaway models were named ADVANCED see picture . In the 1949 March 1 price list they were called REGENT see picture. However many of the earliest c.1949 cutaway models actually have CUTAWAY typed on the label. After c. 1954 (SN 68400) all labels have CUTAWAY typed on the label.”

BINDING

Epiphone used on all instruments Dupont cellulose nitrate plastic material called Pyralin in the 1930s, referred to as ivoroid in the 1940s and 1950s. The complexity of binding increased up the line, from a single white strip on the less expensive guitars to an elaborate, thirteen-ply white/black pattern on the body of the Emperor.

FINISH

Epiphone used a nitrocellulose lacquer on all their instruments. Until approximately 1939 a golden sunburst adorned all guitars. After that a natural finish was offered on the Emperor and De Luxe. By 1941 this option was also available on the Broadway, Triumph, Blackstone, Spartan and Ritz. After the introduction of the natural option, the sunburst finish was referred to as “regular” finish.

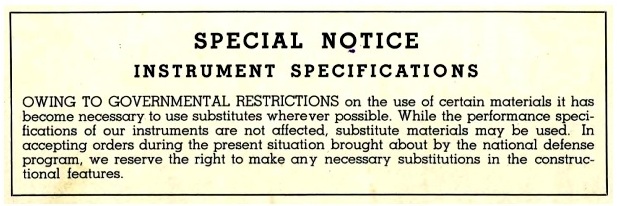

“In 1943 the top finish of archtops changed to an opaque quality – in both sunburst and blonde finish instruments, the latter showing an “ivory opaque” top finish often yellowed today. I believe that the opaque finish was actually introduced to conceal the wood grain, because during the war years shortages in top quality spruce seem to have prompted Epiphone to use a different wood species for some carved tops – possibly birch or poplar(?). There are examples stripped of their originally opaque finish showing an unusual wood grain pattern. However so far I never had the opportunity to personally examine such an example.” (Wiedler : close-up # 02)

Epiphone catalog 1942

NOTE: Epiphone guaranteed “All models for the life of the instrument” (cat. 1932), but “metal and other parts that recieve wear, excepted” (cat. 1934), since they don’t last such a long period. Therefore many of the historic guitars most likely don’t have their original binding (fully or partly rebound) or original finish anymore (fully refinished, partly refinished or touched up).

References:

Felix Wiedler, NY Epi Reg

Jim Fisch & L.B. Fred, The House of Stathopoulo, 1996, pp. 66-77